The lift trucks are used to unload, lift, lower and stack pallet loads, or other bulk loads into storage and transportation racks and facilities. Items such as computers, drums, corrugated boxes, plastic bottles, furniture and beverages are examples of products which are stacked onto pallets and moved by reach trucks. Read More…

We create forklifts that are ideal for rough terrain environments. These powerful machines offer superior lifting strength but they are also very easy to use. Our outstanding products are reinforced with the highest quality resources available. These units come with unmatched quality and the consistency is guaranteed. We will tailor our processes to adhere to your timetables.

Our goal at Crown Equipment Corporation is to provide you with the very best forklift trucks. These items are extremely reliable and can handle the toughest loads. We are eager to work with your business. We offer competitive pricing for premium quality forklifts.

At Mitsubishi Logisnext Americas, we design and build forklift trucks that help businesses move smarter, safer, and more efficiently. Our portfolio covers electric and internal combustion lift trucks engineered for performance across manufacturing, distribution, and warehousing operations.

Since 1917, CLARK has been one of the forklift industry`s most progressive manufacturers, continuously seeking to improve product, expand service and provide value to its customers. A full line of varying precision manufactured equipment ranging from 1,500 to 18,000 pound capacities serve the needs of industrial clients around the world. Please call CLARK today with any questions you may have.

More Reach Truck Manufacturers

Maximizing Warehouse Efficiency with Reach Trucks and Industrial Forklifts

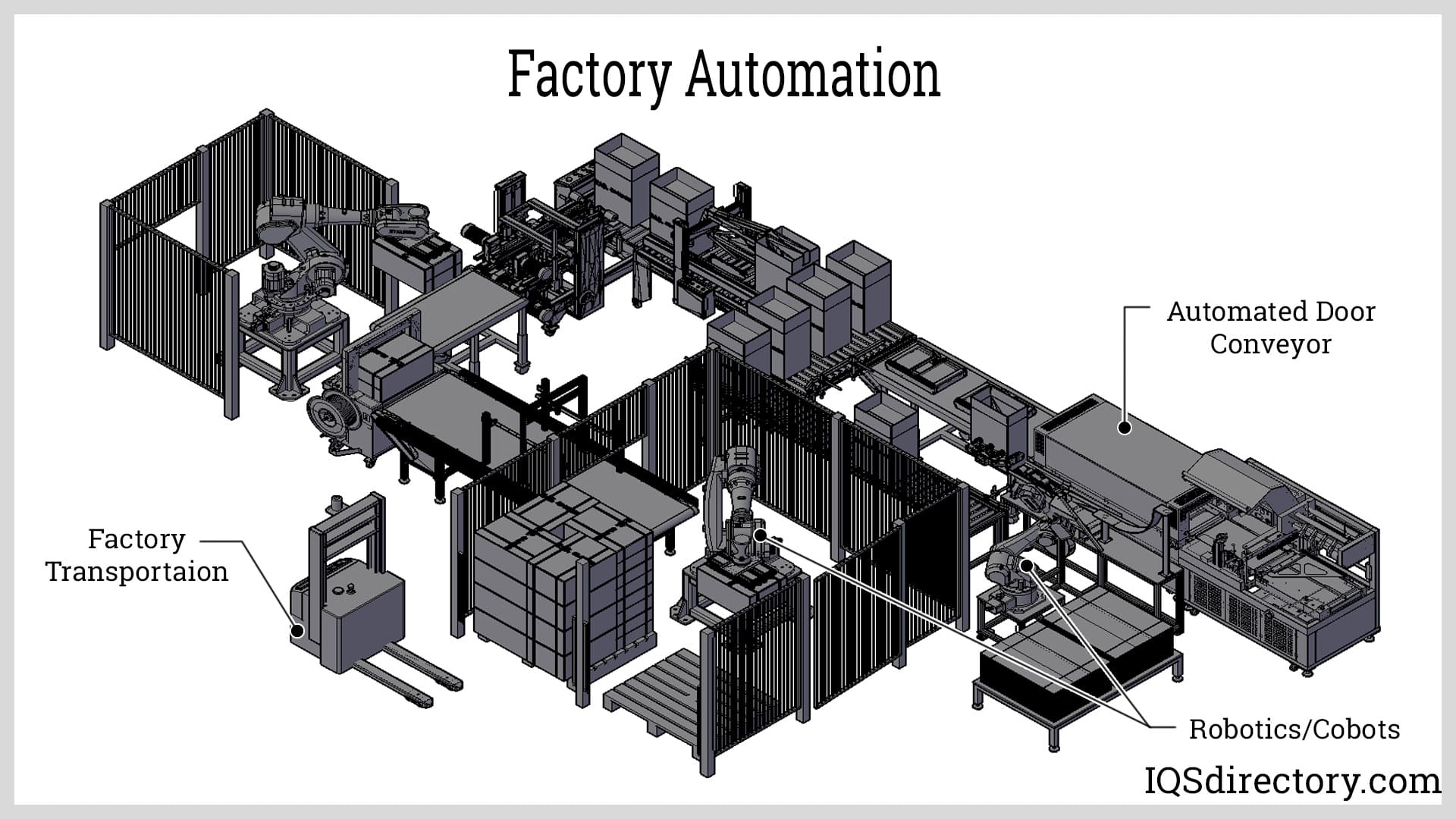

Efficient storage solutions are a critical operational focus for warehouse managers, logistics facilities, and industrial space owners seeking to optimize space, streamline inventory management, and boost productivity. Forklift trucks, including specialized reach trucks, play an essential role in maximizing vertical storage capacity and improving material handling operations. By enabling the safe movement of heavy loads to elevated racking systems, industrial trucks support a wide range of industries, from manufacturing and distribution to retail and third-party logistics (3PL) services.

What Are Reach Trucks and How Do They Work?

Reach trucks are a specialized type of industrial forklift designed specifically for use in narrow aisles and confined warehouse storage areas. Their core function is to lift, lower, and transport palletized goods—sometimes weighing thousands of pounds—using a hydraulic lifting mechanism. Unlike traditional forklifts, reach trucks are engineered for exceptional maneuverability, allowing operators to navigate tight corners and densely packed shelving with ease. This makes them indispensable in modern high-density storage environments.

Key features of reach trucks include:

- Outriggers or stabilizing arms at the front of the truck, providing stability when lifting heavy or high loads.

- Telescoping forks equipped with advanced hydraulic lifting systems, enabling the precise raising of pallets and materials to reach high shelves, racks, or mezzanine storage levels.

- Options for high-strength, heavy-duty masts for intensive industrial applications or when handling exceptionally heavy loads.

- Ergonomic operator controls for improved safety and efficiency in repetitive material handling tasks.

Reach trucks are typically powered by either internal combustion engines (for outdoor or heavy-duty use) or electric motors (favored for indoor applications due to zero emissions and quieter operation). The choice between these power sources depends on factors such as warehouse ventilation, load requirements, and sustainability initiatives.

Types of Reach Trucks: Choosing the Right Model for Your Application

When evaluating reach trucks for purchase or lease, it’s vital to understand the different types available and how they align with your operational requirements. The three most common types of reach trucks are:

- Straddle Reach Trucks: Featuring wider bases for enhanced stability, these trucks are engineered to handle extremely heavy loads at maximum lift heights. The outriggers straddle the pallet, allowing for secure lifting and placement even in tall racking systems. Ideal for warehouses with frequent high stacking and variable load sizes.

- Stand-Up Reach Trucks: These models allow operators to quickly enter and exit the cab, making them well-suited for operations that require frequent on-off cycles and high throughput. Stand-up reach trucks are known for their agility, allowing for fast pallet retrieval and placement in busy warehouse environments.

- Double Deep Reach Trucks: Equipped with extended-length forks, double deep reach trucks can access two pallet positions deep within double-deep racking systems. This design maximizes storage density, reducing required aisle width, and is perfect for facilities looking to increase pallet positions without expanding their physical footprint.

Curious about which reach truck is best for your warehouse? Compare reach truck features, operator ergonomics, and load capacities to select the optimal model for your unique storage and handling needs.

Advantages of Using Reach Trucks in Warehouse Operations

The adoption of reach trucks delivers several significant advantages for warehouse and distribution center operations. Here’s how reach trucks can transform your material handling processes:

- Maximized Storage Density: By taking advantage of vertical space, reach trucks enable you to store more inventory within the same square footage, minimizing real estate costs and boosting inventory capacity.

- Improved Productivity: With their tight turning radius and precise control systems, reach trucks accelerate pallet movement, reducing picking and stocking times for order fulfillment.

- Optimized Space Utilization: Narrow aisle reach trucks allow for racking to be placed closer together, increasing usable storage space without sacrificing accessibility or safety.

- Easy Pallet Load Retrieval: Advanced hydraulic and electronic controls enable operators to safely and efficiently retrieve pallets from high or deep racking, minimizing the risk of product damage.

- Reduced Labor Costs: Automated and semi-automated reach truck models can streamline repetitive tasks, freeing up workforce resources for higher-value activities.

- Enhanced Operator Safety: Ergonomically designed cabs, visibility enhancements, and intelligent control systems help reduce workplace accidents and strain-related injuries.

- Lower Environmental Impact: Electric reach trucks produce zero emissions, supporting your facility’s sustainability and environmental compliance goals.

Looking to lower operational costs and increase warehouse throughput? Explore the full range of reach truck solutions designed to meet the evolving demands of the modern supply chain.

Key Applications and Industry Use Cases for Reach Trucks

Reach trucks are invaluable in a variety of storage and logistics environments, including:

- Warehousing and Distribution: Core equipment for moving inventory between receiving, storage, and shipping zones.

- Manufacturing: Essential for supplying assembly lines with raw materials and transporting finished goods to staging areas.

- Cold Storage and Food Distribution: Electric reach trucks are ideal for temperature-controlled environments, where emissions and heat must be minimized.

- Retail and E-commerce Fulfillment: Reach trucks support fast, accurate picking and replenishment in high-volume, SKU-diverse settings.

- 3PL and Logistics Providers: Flexible enough to handle diverse client requirements, from bulk pallet storage to small-item picking.

- Automotive and Heavy Industry: Straddle reach trucks and double deep models handle oversized or unusually heavy loads in production and parts storage areas.

Wondering if reach trucks are right for your business? Consult with a material handling expert to conduct a warehouse needs assessment and determine the most effective equipment solutions for your operational goals.

Factors to Consider When Selecting a Reach Truck

Choosing the best reach truck for your warehouse or industrial facility involves careful consideration of several factors. Here are some key decision points to guide your selection process:

- Load Capacity: Evaluate the maximum weight and dimensions of the loads your reach truck will handle. Over-specifying can increase costs, while under-specifying can limit operational efficiency and safety.

- Lift Height Requirements: Analyze the height of your storage racks or shelving systems to ensure the reach truck’s mast can safely and reliably access all pallet positions.

- Aisle Width: Measure the width of your warehouse aisles to determine the turning radius and chassis size needed for efficient navigation.

- Power Source: Decide between electric and internal combustion models based on operational environment, maintenance preferences, and energy usage goals.

- Operator Ergonomics: Prioritize equipment with comfortable controls, adjustable seating (or standing platforms), and panoramic visibility to enhance operator performance and reduce fatigue.

- Technology and Automation: Consider reach trucks with advanced features such as load sensors, camera systems, fleet management software, and semi-automated navigation for future-proofing your operations.

- Maintenance and Support: Ensure parts availability, technical support, and scheduled maintenance plans to minimize downtime and extend equipment lifespan.

- Cost of Ownership: Factor in not only the upfront purchase or leasing costs but also long-term expenses like energy consumption, routine maintenance, operator training, and potential resale value.

Need help selecting the right reach truck? Request a free quote and site assessment from leading material handling equipment providers to compare models and pricing.

Reach Truck Safety Guidelines and Operator Training

While reach trucks deliver significant productivity and space-saving benefits, they also introduce certain operational risks. Proper operator training and adherence to safety guidelines are essential for minimizing accidents, product loss, and workplace injuries. Consider these best practices:

- Comprehensive Operator Training: Invest in certified training programs that cover machine operation, load handling, and emergency procedures. This is critical for regulatory compliance and reducing liability.

- Regular Safety Inspections: Conduct pre-shift checks on hydraulic systems, brakes, tires, controls, and warning devices to identify potential hazards before operation.

- Safe Load Handling: Instruct operators to always check load stability, ensure even weight distribution, and never exceed rated lift capacities.

- Awareness of Surroundings: Operators must remain alert to aisle traffic, overhead obstacles, and pedestrian activity to prevent collisions and injuries.

- Fatigue Mitigation: Extended operation at high lift heights (up to 40ft) can strain the operator’s neck and eyes. Schedule regular breaks and rotate job responsibilities to minimize fatigue-related errors.

- Clear Signage and Markings: Maintain visible aisle markings, racking load limits, and safety signage throughout your facility to reinforce best practices.

- Continuous Improvement: Encourage feedback from operators and supervisors to improve safety protocols and address emerging risks.

Looking for reach truck safety resources? Browse OSHA guidelines and industry best practices to ensure compliance and protect your workforce.

Comparing Reach Trucks vs. Other Forklift Types

It’s important to understand the differences between reach trucks and other common forklift types when planning your warehouse layout or fleet expansion. Here’s a quick comparison:

- Counterbalance Forklifts: Versatile, suitable for both indoor and outdoor use, but require wider aisles and are less efficient in high-density storage environments.

- Pallet Stackers: (Learn more about pallet stackers) Ideal for lighter loads and short-distance transport, but lack the height and capacity of reach trucks.

- Order Pickers: Designed for manual picking of individual items at various heights, rather than moving entire pallets.

- Turret Trucks: Offer maximum flexibility for very narrow aisle (VNA) operations, but often come with higher initial costs and maintenance requirements.

Not sure which forklift is right for your needs? Compare reach trucks with counterbalance, order picker, and turret truck models to find the ideal solution for your storage and throughput requirements.

Cost Considerations and Total Cost of Ownership

Budgeting for reach trucks involves more than just the purchase price. To calculate total cost of ownership (TCO), factor in:

- Initial Investment: Purchase or leasing costs, including optional attachments, safety features, and extended warranties.

- Operating Expenses: Energy usage (electricity or fuel), periodic maintenance, and replacement parts.

- Training and Certification: Ongoing operator training, safety certification renewals, and compliance costs.

- Downtime Risk: Potential productivity losses due to breakdowns or unplanned maintenance can impact your bottom line.

- Resale and Upgrade Value: Well-maintained reach trucks retain value and can be traded in for newer models as operational needs evolve.

- Tax Incentives: Explore available federal, state, or local incentives for investing in energy-efficient or electric-powered material handling equipment.

Ready to budget for new reach trucks? Contact trusted forklift dealers for detailed cost analysis, financing options, and potential return on investment (ROI) calculations.

Emerging Trends in Reach Truck Technology

As warehouse automation and digital transformation accelerate, reach trucks are evolving to incorporate advanced technologies that improve efficiency, safety, and data-driven decision making. Some of the latest innovations include:

- Telematics and Fleet Management: Real-time tracking of equipment usage, maintenance status, and operator performance helps optimize fleet utilization and reduce costs.

- Automated Guided Vehicles (AGVs): Semi- and fully-automated reach trucks can perform repetitive transport and storage tasks with minimal human intervention, increasing consistency and reducing labor needs.

- Energy-Efficient Batteries: Lithium-ion battery systems offer faster charging, longer run times, and lower maintenance than traditional lead-acid batteries.

- Integrated Safety Features: Proximity sensors, collision avoidance systems, and operator-assist technologies help prevent accidents and protect personnel.

- IoT Connectivity: Smart reach trucks can communicate with warehouse management systems (WMS) for real-time inventory tracking, automated replenishment, and predictive maintenance scheduling.

- Ergonomic Enhancements: Adjustable controls, climate-controlled cabs, and improved visibility features support operator comfort and productivity during long shifts.

Interested in future-proofing your operations? Explore smart reach trucks and automation solutions to keep pace with warehouse technology trends and stay ahead of the competition.

Frequently Asked Questions About Reach Trucks

- What is the difference between a reach truck and a standard forklift?

Reach trucks are designed for narrow aisles and high stacking, featuring extendable forks and outriggers for stability. Standard forklifts (counterbalance forklifts) offer greater versatility but require wider aisles and are less efficient for high-density storage. - Can reach trucks be used outdoors?

While most reach trucks are optimized for indoor use on smooth surfaces, there are specialized models with larger tires and weather protection for limited outdoor applications. For heavy-duty outdoor work, consider internal combustion or rough-terrain forklifts. - How high can a reach truck lift?

Modern reach trucks can typically lift loads to heights between 20 and 40 feet, depending on model and mast configuration. - How much training is required for reach truck operators?

OSHA and similar regulatory bodies require comprehensive operator training and certification, including written and practical assessments. - What maintenance is required for reach trucks?

Regular inspections, battery or fuel system maintenance, hydraulic checks, and safety system testing are essential for safe, reliable operation. - Are electric reach trucks better than internal combustion models?

Electric reach trucks are preferred for indoor use due to zero emissions and lower operating noise, while internal combustion models offer more power for heavy-duty or outdoor tasks. - What is the typical lifespan of a reach truck?

With proper maintenance, reach trucks can last 10 years or longer, though actual lifespan depends on usage intensity, environment, and adherence to service schedules.

Start Transforming Your Warehouse with Reach Trucks

Reach trucks are an indispensable asset for any facility looking to maximize storage efficiency, enhance material handling productivity, and future-proof warehouse operations. Whether you are managing a distribution center, manufacturing plant, retail fulfillment hub, or multi-client 3PL facility, the right reach truck can make a measurable difference in your bottom line.

Ready to take the next step? Contact our expert team today for a personalized consultation, equipment recommendations, and competitive pricing on the latest reach truck models. Or, learn more about related warehouse equipment solutions to further optimize your facility’s material handling capabilities.

Have specific questions? Ask about custom configurations, financing options, or on-site demonstrations to see firsthand how reach trucks can transform your warehouse operations. Empower your team and unlock new levels of efficiency with industry-leading reach truck technology.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches