Forklifts, or forklift trucks, are industrial trucks designed to lift and move loads. Forklifts can increase efficiency, reduce the risk of injury, and enhance storage space. Forklift trucks have an extensive range of lifting capabilities. They can lift and move anything from bulk materials to heavy duty equipment. Read More…

We create forklifts that are ideal for rough terrain environments. These powerful machines offer superior lifting strength but they are also very easy to use. Our outstanding products are reinforced with the highest quality resources available. These units come with unmatched quality and the consistency is guaranteed. We will tailor our processes to adhere to your timetables.

Our goal at Crown Equipment Corporation is to provide you with the very best forklift trucks. These items are extremely reliable and can handle the toughest loads. We are eager to work with your business. We offer competitive pricing for premium quality forklifts.

At Mitsubishi Logisnext Americas, we design and build forklift trucks that help businesses move smarter, safer, and more efficiently. Our portfolio covers electric and internal combustion lift trucks engineered for performance across manufacturing, distribution, and warehousing operations.

Since 1917, CLARK has been one of the forklift industry`s most progressive manufacturers, continuously seeking to improve product, expand service and provide value to its customers. A full line of varying precision manufactured equipment ranging from 1,500 to 18,000 pound capacities serve the needs of industrial clients around the world. Please call CLARK today with any questions you may have.

More Forklift Manufacturers

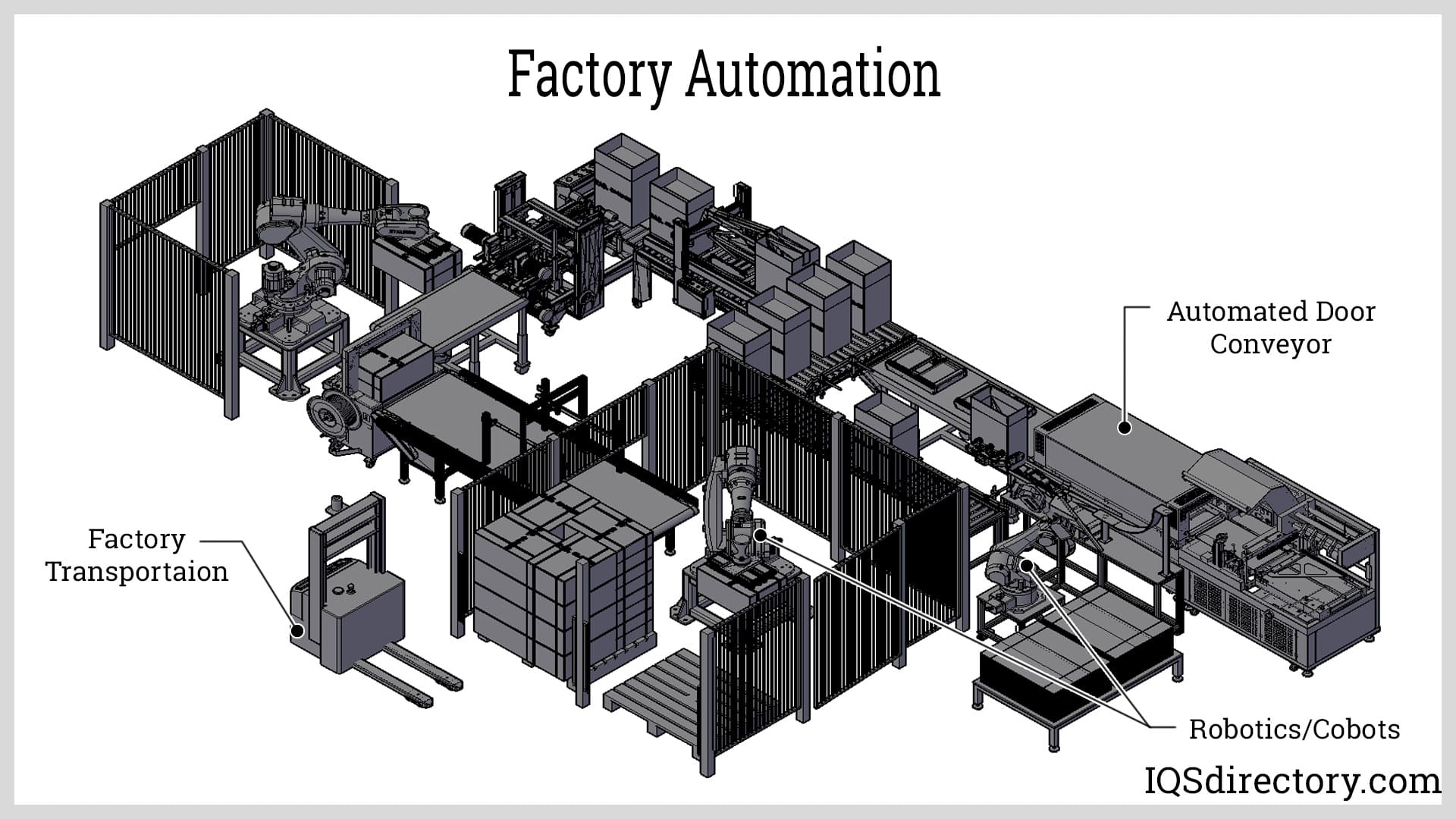

Forklift trucks are indispensable pieces of material handling equipment, vital for a wide range of industries including logistics, warehousing, shipping, manufacturing, aerospace, automotive, marine, construction, and product handling. These versatile industrial vehicles are designed to lift, transport, and stack heavy pallets and materials efficiently and safely, optimizing operations in both industrial and commercial warehouses. Their ability to handle large loads with precision makes them a cornerstone of supply chain management and inventory control.

In warehousing and distribution centers, forklifts enable organizations to maximize storage density by stacking loaded pallets as high as the building structure allows. This efficient use of vertical space enhances inventory management, reduces operational costs, and supports just-in-time delivery systems. On construction sites, forklifts move heavy building materials and equipment, improving site safety and workflow. In shipping and loading docks, forklifts are essential for loading and unloading goods from trucks, railcars, and shipping containers, streamlining inbound and outbound logistics.

History of Forklift Trucks

The evolution of the forklift is deeply rooted in the development of hydraulic technology. The origin traces back to Blaise Pascal, whose discovery of hydraulic power in 1647–1648 established the foundation for the modern forklift’s lifting mechanism. Pascal’s Law, stating that pressure applied to a confined liquid is transmitted equally throughout the liquid, is the underlying principle of all hydraulic systems used in today’s forklifts.

Forklift technology first emerged during World War I, driven by the need for efficient material handling in the face of labor shortages. American companies developed the earliest forklift prototypes powered by hydraulics, revolutionizing warehouse and factory operations. The Clark company was a pioneer, selling “Trucktractors”—the first forklifts that combined the features of trucks and tractors—while Yale & Towne introduced the concept of elevating loads above truck height in 1923. The adoption of standardized pallets after World War I propelled the popularity of forklifts, making them essential for efficient handling and movement of goods.

During World War II, the demand for rapid military logistics led to mass production of forklifts, enabling the efficient shipment of materials and equipment. Advances in forklift design in the post-war era focused on operator safety, incorporating features such as safety cages, improved lifting capacities, battery-powered electric motors, and enhanced maneuverability for tight spaces. The advent of counterbalances, electronic controls, and computer numerical control (CNC) automation from the 1960s to the 1980s further transformed forklift performance, accuracy, and operator comfort. Today, the forklift market is highly competitive, with electric forklifts growing in demand due to strict emissions regulations and the need for environmentally friendly solutions.

How Forklifts Work

Understanding how forklifts operate is crucial for anyone considering purchasing, renting, or operating these powerful material handling machines. At the core of most forklifts is a hydraulic lifting system that generates immense force, enabling the equipment to raise and lower heavy loads with precision. Some specialized models utilize electric actuator-controlled lifts for certain applications, but hydraulics dominate due to their reliability and efficiency.

Forklift operation can be classified into three main control styles: manual, motorized, and automated. Each style is tailored for specific operational needs and environments:

- Manual forklifts rely on human power for movement and operation. Operators push or pull the forklift from behind, making these models ideal for small-scale warehouses, retail stockrooms, and environments where precise, low-speed handling is required.

- Motorized forklifts feature electric or internal combustion engines, allowing operators to sit or stand while driving. These powered industrial trucks are best suited for larger facilities, manufacturing plants, and distribution centers where efficiency, speed, and high load capacity are key requirements. Motorized forklifts significantly reduce operator fatigue and improve productivity.

- Automated forklifts—such as Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs)—are equipped with advanced computer-guided navigation systems. These smart forklifts can transport goods without direct human control, streamlining repetitive tasks in industries like automotive manufacturing, aerospace, and high-volume ecommerce fulfillment. Their precision, efficiency, and ability to operate around the clock contribute to increased throughput and reduced labor costs.

Wondering how to choose the best forklift control style for your facility? Contact our experts for a needs assessment or explore our forklift selection guide to match your requirements with the right technology.

Types of Forklifts

When selecting a forklift, it’s important to consider the variety of forklift types available, each designed to address distinct operational challenges and environments. Leading forklift suppliers offer a range of models to ensure that every industry need is met. Here are the primary types of forklifts and their typical applications:

- Walkie Forklifts: These compact, electric-powered forklifts are engineered for smooth, indoor surfaces such as those in warehouses, factories, and retail distribution centers. Their specialized wheels and quiet operation make them perfect for environments where cleanliness and noise reduction are priorities. Walkie forklifts excel at short-distance material transportation and are often used for loading and unloading pallets, order picking, and replenishing stock in narrow aisles.

- Sideloaders: Sideloaders feature a unique, side-mounted lifting platform, enabling them to carry long or bulky loads—such as pipes, lumber, or sheet materials—without compromising maneuverability. They are particularly valuable in industries that require handling of oversized items in narrow aisles or tight warehouse spaces. Sideloaders provide stability and safety when transporting heavy, awkward loads, making them a top choice for lumberyards, steel mills, and manufacturing plants with specialized storage needs.

- Platform Trucks: While not strictly considered industrial forklifts, platform trucks are robust, flatbed vehicles designed for moving pallets and other goods across warehouse floors or onto trailers. Their simple construction and manual or powered steering mechanisms make them a cost-effective solution for environments that require frequent horizontal movement of goods without the need for vertical lifting.

- Straddle Trucks: With a widened base and heavy-duty construction, straddle trucks are built for lifting larger, heavier loads to greater heights. Their enhanced stability and lifting capacity are ideal for industrial applications such as heavy manufacturing, foundries, and large-scale distribution operations. Straddle trucks are often chosen for tasks that require both strength and reach, such as stacking pallets in multi-level racking systems.

- Stand-Up Forklifts: Designed for operator efficiency and fast-paced environments, stand-up forklifts eliminate the need for a seat, allowing operators to easily enter and exit the vehicle during frequent loading and unloading cycles. Their compact size and tight turning radius make them ideal for high-density warehouses and areas where maneuverability is critical. Stand-up forklifts are widely used in beverage distribution, grocery warehouses, and retail fulfillment centers.

- Narrow Aisle Forklifts: Engineered specifically for maximizing storage space, narrow aisle forklifts are capable of operating in aisles as tight as five to seven feet wide. Their slender design, advanced steering, and precision controls enable efficient handling and retrieval of goods in space-constrained warehouses. These forklifts are essential for businesses seeking to increase storage density and improve inventory management. Learn more about narrow aisle forklifts.

- Order Picker Trucks: Also referred to as reach trucks or warehouse forklifts, order pickers enable operators to access and retrieve products stored on high shelves. Their extendable platforms and elevated controls are perfect for order fulfillment centers, ecommerce warehouses, and any operation that requires efficient picking of individual items from racking systems.

- Turret Forklifts: Turret forklifts distinguish themselves by the ability to rotate loads up to 90 degrees, enabling precise placement and retrieval of goods in very narrow aisles and tall storage racks. Their advanced maneuverability and lifting capabilities make them ideal for high-bay warehousing, cold storage facilities, and automated storage and retrieval systems (AS/RS).

Not sure which forklift type is right for your application? Try our interactive forklift selection tool or contact a specialist for a custom recommendation.

Forklift Classes

To simplify the process of selecting the right forklift, the industry categorizes forklifts into seven distinct classes, each based on tire type, engine type, and application environment. Understanding these classes will help you choose the equipment that best fits your operational requirements:

- Class 1: Electric Motor Rider Trucks. These forklifts feature electric drive motors and are available in both sit-down and stand-up configurations. Their three-wheel or four-wheel designs offer superior maneuverability, making them ideal for indoor applications such as warehousing, food processing, and electronics manufacturing. Class 1 forklifts are known for their quiet operation, zero emissions, and energy efficiency, making them a popular choice for businesses focused on sustainability and indoor air quality.

- Class 2: Electric Motor Narrow Aisle Trucks. Specially engineered for environments with limited space, Class 2 forklifts excel in narrow aisle storage systems. Their advanced features, such as swing masts and extendable forks, allow operators to access hard-to-reach pallets and maximize storage density. These forklifts are commonly used in high-density warehouses, order fulfillment centers, and facilities with automated racking systems.

- Class 3: Electric Motor Hand or Hand/Rider Trucks. Class 3 forklifts are versatile, walk-behind or ride-on pallet trucks used for horizontal transport of pallets and goods. They offer user-friendly controls and are designed for short-distance movement within warehouses, supermarkets, and retail stores. High lift models and pallet stackers provide additional lifting functionality for stacking and organizing inventory.

- Class 4: Internal Combustion Engine Trucks with Cushion Tires. Designed primarily for indoor use, these forklifts feature powerful internal combustion (IC) engines and smooth cushion tires. They are ideal for handling heavy loads on concrete or smooth surfaces, commonly found in manufacturing plants, distribution centers, and logistics hubs. Seated controls and ergonomic cabs enhance operator comfort and productivity.

- Class 5: Internal Combustion Engine Trucks with Pneumatic Tires. Similar to Class 4, Class 5 forklifts are equipped with IC engines but have rugged pneumatic tires that provide better traction and stability on uneven or outdoor surfaces. These forklifts are suitable for construction sites, lumber yards, and other environments where terrain can be unpredictable.

- Class 6: Electric and Internal Combustion Engine Tractors. This class includes tow tractors and platform trucks powered by electric or internal combustion engines. Their flexibility allows them to move trailers, carts, and materials across indoor and outdoor sites, supporting diverse logistics and manufacturing operations.

- Class 7: Rough Terrain Forklifts. Specifically engineered for off-road use, rough terrain forklifts are equipped with large, heavy-duty pneumatic tires and robust suspension systems. They are built to navigate construction sites, lumber yards, agricultural operations, and other challenging environments where conventional forklifts would struggle.

Curious about which forklift class matches your operational needs? Browse our in-depth forklift class comparison guide or request a consultation with one of our forklift specialists.

Key Components of Forklifts

Understanding the main components of a forklift is essential for safe operation, effective maintenance, and informed purchasing decisions. Forklift trucks include the following essential parts:

- Wheels and Tires: Forklifts may use solid rubber or pneumatic tires, tailored for indoor or outdoor use. Outriggers can be added for increased stability during heavy lifting tasks.

- Forks or Lift Platforms: The load handling area, typically featuring adjustable forks to accommodate different pallet sizes. Some models include attachments like clamps, rotators, or side shifters to increase versatility.

- Lift Mechanism: Hydraulic cylinders or electric actuators power the vertical movement of the forks. This system is central to the forklift’s lifting capability and efficiency.

- Operator Controls: Located either beside the driver’s seat or on a standing platform, these controls enable precise operation of lifting, lowering, steering, and speed.

- Engine or Power Source: Forklifts are powered by internal combustion engines (using diesel, gasoline, LPG, or CNG) or electric motors (powered by rechargeable batteries). The choice of power source impacts emissions, operating costs, and maintenance requirements.

- Safety Features: Modern forklifts are equipped with advanced safety systems, including alarms, horns, flashing lights, headlights, signal lights, seat belts, guard rails, speed limiters, and operator presence sensors. These features protect both operators and nearby personnel.

Many forklifts also incorporate ergonomic designs and adjustable seats to minimize operator fatigue during long shifts. Some advanced models offer telematics systems for real-time monitoring of performance and maintenance needs.

Forklift Safety: Best Practices and Compliance

While forklifts dramatically improve productivity, improper use can pose serious safety risks. Adhering to rigorous forklift safety protocols is essential to protect workers, prevent accidents, and comply with Occupational Safety and Health Administration (OSHA) regulations. Here’s a comprehensive guide to safe forklift operation:

- Pre-Operation Inspection: Before each shift, inspect the forklift for visible damage, leaks, or malfunctions. Check tires, connectors, hoses, brakes, hydraulic tubing, forks, and fluid levels. Address any issues before operating the equipment.

- Mounting and Starting: Always use designated handholds when entering or exiting the forklift. Avoid jumping from the vehicle to prevent injuries. Once seated, secure your seatbelt and conduct a functional test of all controls, lights, alarms, and safety devices.

- Environmental Awareness: Survey the area for obstructions, personnel, and other vehicles. Adjust mirrors for optimal visibility, communicate with nearby workers, and ensure the path is clear before moving.

- Operation Practices: Drive at safe speeds, especially when carrying heavy or elevated loads. Navigate turns cautiously and never turn with a raised load. When reversing, check behind you and use audible signals if visibility is limited. Keep loads centered, within the forklift’s rated capacity, and be mindful of overhead clearance.

- General Safety Recommendations:

- Avoid operating forklifts outside designated areas.

- Do not turn on inclines or ramps.

- Use gradual braking rather than sudden stops.

- Employ spotters or follow marked paths in congested environments.

- Never attempt to lift loads exceeding the forklift’s maximum capacity.

- Ensure even distribution and securement of loads on the forks.

- Be vigilant of low ceilings, sprinkler systems, and overhead obstacles when raising loads.

Buying, Renting, and Maintaining Forklifts: Key Considerations

Choosing the right forklift for your business involves several critical factors, including intended application, load capacity, lift height, power source, operational environment, and budget constraints. Here’s what to consider when evaluating your options:

- New vs. Used Forklifts: New forklifts offer the latest technology, advanced safety features, and full manufacturer warranties, making them ideal for businesses prioritizing reliability and low maintenance. Used or refurbished forklifts, when sourced from reputable suppliers, can provide substantial cost savings and reliable performance—especially for operations with lighter usage requirements or limited budgets.

- Leasing and Rental Options: Forklift rental and leasing programs provide flexibility for businesses with seasonal fluctuations, temporary projects, or evolving needs. These options reduce upfront capital expenditures and often include maintenance, reducing operational risk.

- Maintenance and Service: Regular preventative maintenance is essential for maximizing equipment lifespan and minimizing downtime. Leading forklift manufacturers and dealers offer service contracts, onsite repairs, and access to genuine replacement parts. Choosing a supplier with responsive customer support and a strong service network ensures ongoing productivity and safety compliance.

- Attachments and Customization: Enhance forklift versatility with attachments such as side shifters, rotators, clamps, and fork extensions. Customizing forklifts for specific material handling tasks increases operational efficiency and safety.

- Regulatory Compliance: Ensure all forklifts meet OSHA and local regulatory requirements, including operator certification, equipment labeling, and regular safety inspections.

Looking for expert advice on purchasing or renting forklifts? Request a quote from our trusted suppliers or compare forklift models and pricing in our buyer’s guide.

Why Partner with a Trusted Forklift Manufacturer or Dealer?

Working with an experienced forklift manufacturer or dealership ensures access to high-quality products, comprehensive after-sales support, and tailored solutions for your unique operational needs. Top suppliers not only provide new and used forklifts but also offer maintenance, repair, and operator training services to maximize your investment and ensure safe, efficient operation. Review supplier profiles, read customer testimonials, and contact sales representatives to discuss your requirements in detail. Comparing service offerings, warranties, and pricing will help you make an informed decision and secure the best value for your business.

Ready to take the next step? Browse our curated list of top forklift manufacturers and dealers or contact us to connect with a material handling expert who can help you evaluate your options and optimize your operations.

For more information on forklift selection, safety, and best practices, explore our in-depth resource center or ask our team a question—we’re here to help you make the most informed decision for your material handling needs.

What industries commonly use forklift trucks?

Forklift trucks are commonly used in logistics, warehousing, shipping, manufacturing, aerospace, automotive, marine, construction, and product handling industries for lifting, transporting, and stacking heavy materials efficiently and safely.

What are the main types of forklifts?

The main types of forklifts include walkie forklifts, sideloaders, platform trucks, straddle trucks, stand-up forklifts, narrow aisle forklifts, order picker trucks, and turret forklifts, each designed for specific applications and operational environments.

How are forklifts categorized by class?

Forklifts are categorized into seven classes based on tire type, engine type, and use: Class 1 (Electric Motor Rider Trucks), Class 2 (Electric Motor Narrow Aisle Trucks), Class 3 (Electric Motor Hand or Hand/Rider Trucks), Class 4 (IC Engine with Cushion Tires), Class 5 (IC Engine with Pneumatic Tires), Class 6 (Electric and IC Engine Tractors), and Class 7 (Rough Terrain Forklifts).

What are the key components of a forklift truck?

Key components of forklift trucks include wheels and tires, forks or lift platforms, lift mechanism (hydraulic or electric), operator controls, engine or power source, and various safety features such as alarms, lights, seat belts, and operator presence sensors.

What are best practices for forklift safety?

Best practices include performing pre-operation inspections, using seat belts and handholds, being aware of the operating environment, driving at safe speeds, avoiding overloading or exceeding maximum capacity, following marked paths, and complying with OSHA and local regulations.

Should I buy, rent, or lease a forklift?

Buying new forklifts is ideal for businesses needing the latest technology and reliability, but renting or leasing provides flexibility for temporary projects or seasonal needs. Used forklifts may offer cost savings for lighter usage. Consider application, budget, and maintenance support when deciding.

What should I look for in a forklift manufacturer or dealer?

Choose manufacturers or dealers that offer quality products, after-sales support, operator training, transparent service contracts, and warranties. Compare profiles, customer reviews, and discuss requirements to find the best fit for your operational needs.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches